Many people wring their hands over excessive packaging (and it is outrageously abused and excessive) but the way to deal with packaging is not to ban it, since it serves a purpose. The Zero Waste way to deal with the excesses of packaging is to redesign packaging to be reusable over and over. This is the great advantage of a well-designed cloth bag being used to replace free plastic bags. Most of the cloth bags put forward are not even close to being well-designed. They are so primitive (nothing but two pieces of cloth sewn together with an added handle) that they don’t come close to replacing the cleanliness and other advantages of plastic bags. Bans don’t work. Intelligent design is what is needed.

Let us take as an example, the plastic bags that are universally offered to shoppers by supermarkets and others to pack up their purchases. These are as thin and light as technology can make them, while remaining strong enough to carry products. I won’t go into their problems here, but I take note that the environmental movement hates them and usually wants them banned for good reasons. Creating the maximum of surface area per gram of substance (polyethylene) and putting it in contact with food to be contaminated is an idiotic design concept. Cleaning and reusing become impossible.

A cottage industry of making cloth bags has grown up to try to replace the plastic bags. They usually have a logo printed on them, two cloth handles and are sold cheaply at markets. For many purposes they do the job. But will they last more or less forever? Will they do everything that a package can and should do? One can design better ways to carry products home.

Your bag might want to keep frozen foods cold. It could have an expandable compartment with insulation. You might want to carry a lot of heavy items at once (you could use it for bulk items or at the hardware store too). It would be nice to have robust handles. But handles wear out. Can they be made to be easily repaired or replaced? People laugh at how long it took to put wheels on luggage. Ditto for bags. Why not have wheels, but make them easily slipped off and put inside the bag when not needed? And velcro closures? Which parts of a bag wear out quickly? The corners. Have renewable corner reinforcements. What happens if some overripe fruit is mashed inside? The bag needs to be washable. Or impermeable. That begins to sound like plastic. Why not? These bags are not going to blow around or fill up the ocean or poison sea life. They are designed to last a hundred years with upgrades. This is a good application for plastic, not a throw-away application. They don’t have to eliminate the simple cloth bags but can coexist.

As always, one key is standardization. Instead of having thousands of different designs for these bags, maybe a couple will suffice. Let the parts be interchangeable so that no one has to throw out some unit whose parts can no longer be replaced because one of the hundreds of manufacturers is out of business, as happens today.

Instead of conceptualizing today’s wasteful throw away society and its common throw away assumptions, let’s imagine a world in which customer bags (and all packaging) are the norm, are taken for granted. A common mistake that people make is to imagine that everything stays the same as today but we just put one improvement into the mix. No! Let’s be bold and think about what a conserving system would look like where all of the disposal assumptions of today are gone and replaced by products that are designed to last forever. Perhaps a standardized bag would be hung on a hook which moves along a checkout counter and as goods are checked out , they are put directly into the bag. Perhaps every car comes with a compact little lifter that hooks onto the handles of the (heavy) bag and pulls it up into the car, reminiscent of the needs of wheelchair users today. Let your imagination roam.

Other packaging can also do wonders once it is standardized. For example, elsewhere I have recommended carrying your own plastic containers for food, at a take out place or at a restaurant. An objection is often raised that people will naturally forget to carry their container with them, or be unable to. Here’s what standardization will do. Let every food serving place have its own hard containers available, which they use by charging you a small deposit. Let’s imagine that these containers are the norm. So they can easily put food into one of them. But then you may accumulate dozens, hundreds of these in your home. How do you solve that problem? Do you remember that these are the norm, and standard designs? That means you can bring clean containers back to any vendor and they can reuse them, because they are basically all the same. Any vendor can refund your deposit because he can use them too.

Because these containers are expected to have a long life of many, many years, they will not be made of soft plastic that easily scratches. There are tough, engineered plastics which are not used for today’s disposable or weak versions because their cost will not be amortized over a long life. When standardized containers are reused hundreds or thousands of times, they can be made of the best plastics. Another special property of such plastic may be that if a container is broken or smashed, the plastic is known to be able to be melted and reused. This is not true of most of the cheap plastics used today for weak, short term applications. How about a truly long lived container made of stainless steel?

There are more special features that can affordably be built into these standardized containers because of their long lives. Knock yourself out designing still more features, always keeping high function in mind. Hint: how will the closures work? Can tops be interchangeable? How will vendors apply advertising? How about liquids?

One of the main arguments I put forward against bans is that they don’t solve a problem (the recyclers don’t care about this – they just lash out at the latest “defect”). Solving a problem requires an understanding of the function that needs to be served and then designing a way to satisfy that legitimate function.

Marian Nestle in her book Food Politics (2012) gives an apposite example from food regulation. She admits to being a bit naive when she earlier agreed to a strong recommendation by the US Dept. of Agriculture, a kind of ban in its effect on diet, that fat be removed from foods. The recommendation was released to the American public in this negative form. Just reduce fat, as though fat had no function in the diet. The effect on the American diet was explosive. Suddenly citizens and manufacturers both were looking for ways to implement this negative admonition.

What happened was that the manufacturers searched for new ways to fulfill the essential function of fat, which is to provide texture to food and to convey taste. They invented some artificial fat substances based on carbohydrates that felt a little like eating fat, but those never caught on. The main thing they did was to replace fat with sugar. Then they developed high fructose corn syrup as a huge new source of sugar and the campaign was on. Soda consumption went through the roof. Miss Nestle sees this as the beginning of the obesity epidemic. All because the USDA recommendations were negative – what is bad – rather than positive – what should we have instead. It is the same with a ban on anything that has a function, such as a plastic bag. Desperate, unconsidered measures will not yield good results.

I am not going to go into great detail here, but it should be noted that any product which is reused over and over enjoys greater resource efficiency than low level recycling of just its materials after tearing or crushing it to pieces. Specifically, imagine a cardboard type box which is more robust than present designs and which can be easily separated into pieces (sides, tops etc.) and easily reassembled as needed. This is not hard to design. Not only could one box be used fifty times but a deteriorated top can be renewed with a new one.

Here is a treatment of the cardboard box that Samsung uses to ship large TV’s in.  The context wasn’t clear, but it appears that the cardboard is designed (prescored?) to break into pieces that can make the house shown for a cat. So each box becomes a cat house. Let me ask then, how many boxes of TV’s will be shipped and how many cat houses can be made use of? The number of boxes probably exceeds the number of cat houses wanted by many times. So a few boxes can be used this way but not all of them. This is an example of greenwashing – making a seemingly environmental modification more for the promotional value than for the actual value. Still, it involves a redesign of boxes rather than crushing them for cardboard, so Samsung deserves some kudos for thinking creatively.

The context wasn’t clear, but it appears that the cardboard is designed (prescored?) to break into pieces that can make the house shown for a cat. So each box becomes a cat house. Let me ask then, how many boxes of TV’s will be shipped and how many cat houses can be made use of? The number of boxes probably exceeds the number of cat houses wanted by many times. So a few boxes can be used this way but not all of them. This is an example of greenwashing – making a seemingly environmental modification more for the promotional value than for the actual value. Still, it involves a redesign of boxes rather than crushing them for cardboard, so Samsung deserves some kudos for thinking creatively.

An obvious advantage to a robust design is that the packaging can incorporate special features which might be too expensive for a throwaway design. Things like special labeling features, windows, reinforced corners etc. spring to mind. Expensive surfaces (wood, metal, plastic etc.) can replace the cardboard and the expense would be justified by the large number of uses that it will be put to.

It isn’t even hard to redesign those so-called clamshell packages – those impenetrable plastic shells that can’t be opened without imperiling a finger. Everyone hates them. But imagine if they were in two parts, a top and a bottom, held together with neat little built-in screws in a standard configuration that could not reasonably be removed by a shoplifter but could be removed by a dedicated “unscrewing machine” on the checkout counter. The product could be removed and the package retained for refilling. The system for using such a device could be commercially interesting but I will leave that for another discussion.

When packaging is being discussed, the first and most important response is to design a new generation of packages that can be reused over and over. A key feature of this design is also designing the entire system in which the package is created, filled, distributed, protects its product, can be used in multiple ways, can be franchised, can be disassembled and the market arrangements for farming out these functions.

As if excess packaging were not enough just because it is excess and unneeded, now scientists tell us that packaging was found to contain 3000 unknown chemicals that are leaching into food – chemicals that have never been studied. If packaging were reused forever, we could make it out of safe, if expensive, but known materials which were not full of surprise mysteries because we were trying to save money on each disposable package.

I have dealt with bottles at length elsewhere. But here is a teaser. What about cans? I mean “tin” cans. How could a tuna fish or sardine can or a soup can be redesigned so that it preserved all of the desirable functions of the current design but could be reused many times? This needs to be the subject of a design contest.

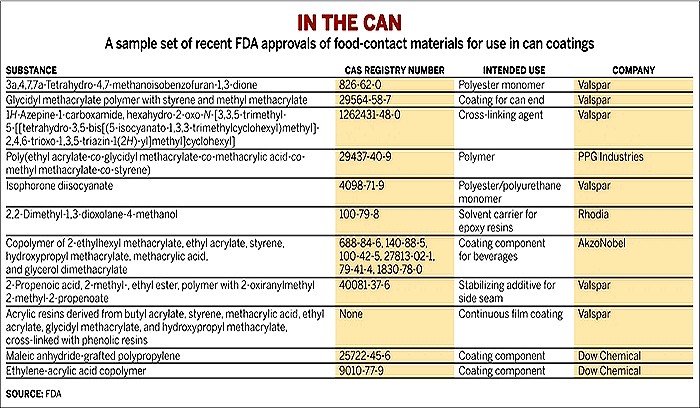

A recent article in Chemical & Engineering News (Feb 11, 2013, p. 24) goes into great detail on the campaign by chemical manufacturers to find a new replacement for the epoxies used to line steel cans. We used to use real tin metal – thus the appellation tin cans – but this has a problem because tin is expensive and we can’t be discarding a few milligrams with every can. Of course we are not allowed to discuss the possibility of NOT discarding cans. Could we use tin coatings if cans were reused many times? I don’t know. The focus of this article is the search for new polymeric coatings. Everyone agrees that epoxies work best but they are made by reaction with bisphenolA (BPA) a chemical that slowly comes out of the coating and causes deleterious biological effects because it mimics estrogen. So the mfrs. are studying polyesters, acrylics, vinyls and natural oil based coatings. None of them can resist food acids, prevent food from contacting the can, survive a ding of the can without cracking, adhere to the metal and be tasteless and odorless. The reason for the search seems to be a bit forgotten. Remember, it was safety. The new list of candidates is a dogs breakfast of complex molecules. Are they safer than BPA? We might want to assume so but no one knows. We will learn the same way we learned about BPA – by using the population as guinea pigs. Whether or not a coating resists tomato sauce and adheres to the can is easy to test in an hour or a day. But safety could take years of exposure to figure out.

Meanwhile, the alternate possibility of designing a container that will not be discarded after a single use is never considered. We have ceramics, glass and even safe polyethylene containers. We have stainless steel. They weigh more, or are more expensive, but what if the weight was dealt with by the user, carrying the empty container to the refilling station to fill it back up? What if an expensive stainless container were able to be used 100 or 500 times? It wouldn’t look so expensive then, but we are not allowed to think of this. These better quality containers that are not discarded don’t need coatings.

This company rents out REUSABLE moving containers. They resemble the large plastic boxes with locking covers that we have become used to. These break, like all rigid plastics and the covers get lost (though always keep in mind that the covers should be standardized so that one cover fits all the commercial boxes). How about making them from thin and collapsible stainless steel, all made in one pack with hinged sides that fold up into a flat package?

Use it once and throw it away. That’s today’s mantra and if we need to spend a billion dollars to make this happen, we spend it gladly. We will spend whatever it takes to pretend to clean up a misbehaving, dangerous, polluting dumpsite (cleaning up the radioactive site of Hanford, Washington is estimated at 760 billions of dollars even though no one has any idea of how it could be done [see Radioactives under Projects]). But not one penny for intelligent design outside the envelope of discard.