If you Google the word fastenings you will discover that there are companies selling thousands of such products using hundreds of different basic designs. It is my purpose to discuss a very few of those here, showing how some common articles can be fastened together in standard ways.

It will come as no surprise that the most common way of fastening two pieces together is by use of screws or bolts. These fasteners come in a quite unnecessary variety of thread sizes, head sizes and lengths. The different heads especially then require a huge variety and sizes of wrenches or drivers to engage the heads. This variety could be severely reduced with little loss of utility but a great gain in interconvertibility.

Another kind of fastener is needed to deal with panels such as are found on dashboards of cars or refrigerator doors. In both cases, there seems to be a consensus by manufacturers that the customer is not allowed to see a screw or understand how the panels are held together. This delusion needs to be abandoned. A few well placed screws that provide the basic fastening would offend no one if they were visible. At the same time, the efforts by erstwhile amateurs to take these panels apart by trial and error would have far less likelihood of breaking or destroying the panels by trying to figure out the hidden fastenings.

When large, two dimensional panels do need to be held together, it would be useful to design a standard way of doing that. For example, edges could be made to be bent over in such a way that they overlap and then a long spline is inserted along the edge that binds the two edges together. The particular design of the edge and spline is not critical, so long as a standard design is adopted so that anyone approaching panels will know exactly where to look and what to expect.

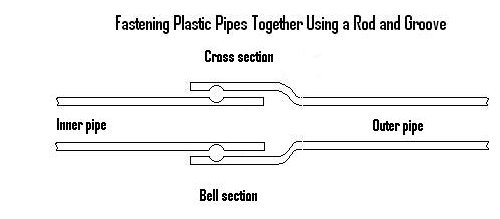

When inserting a casing into a well hole that has been drilled hundreds or thousands of feet into the ground, the pipe sections need to be fastened together as the casing is built and inserted. These casings today are usually made of heavy duty PVC plastic. Formerly, the standard way of fastening sections together was to cement them together at their ends. This formed an indissoluble joint that could not be subsequently opened up, necessitating the cutting of the casing into multiple sections any time it might need to be removed. For sufficiently heavy sections, a new, rather clever way of connecting the sections has come into use. It is shown in this sketch.

The outer pipe has an enlarged section (a bell) that fits over the end of the inner pipe. Each one has a hemispherical groove running all around the pipe such that when the inner pipe is inserted into the bell, the grooves exactly line up. The bell section has a hole drilled into it that connects the outside of the bell to the groove inside. Then a length of round, flexible, PVC rod that will just fit inside the groove is inserted through the drilled hole and forced to circle around the groove, filling it up inside. Now the two sections of pipe can no longer come apart. A bit of the rod is left outside the bell so that it can be pulled out again, thus releasing the two sections of pipe from each other.

The outer pipe has an enlarged section (a bell) that fits over the end of the inner pipe. Each one has a hemispherical groove running all around the pipe such that when the inner pipe is inserted into the bell, the grooves exactly line up. The bell section has a hole drilled into it that connects the outside of the bell to the groove inside. Then a length of round, flexible, PVC rod that will just fit inside the groove is inserted through the drilled hole and forced to circle around the groove, filling it up inside. Now the two sections of pipe can no longer come apart. A bit of the rod is left outside the bell so that it can be pulled out again, thus releasing the two sections of pipe from each other.

There are many other designs for specialized fastenings. But they can all be standardized to use a small number of different pieces rather than the vast number of sizes used today.