Why are we so obsessed here with better product design? Isn’t every product pretty much optimized by its manufacturer for the “best” design? I don’t think that is even close to being true for the simple reason that the manufacturer has blinders on. She has her goals and she designs to achieve them. But other people have a different set of goals.

Designers never think about what will happen when part of their product wears out or breaks or becomes obsolete. If they think about it at all, it is just to assume that it will be discarded into a garbage can like everything else in this wasteful society. What wears out first? In my experience, it’s the bristles, which also happen to be the cheapest part. So how could the brush be designed to make the bristles easy to replace. Right now they are forced with some kind of specialized machine into holes in the wooden head. Is there a way to force in new ones? Or a different way to hold the bristles in place? How about a design that uses a cover over the wooden head which has holes in it for holding the bristle bundles. If a bundle wears out or breaks, another can be inserted by lifting the cover. The bristle bundles can come as an intended repair with ten bristles secured by a dab of glue at the end creating one bundle. The bristles could be a natural protein such as hog bristles, so that the brush can be composted if and when it breaks so badly there is simply no way to repair it.

It would be a start.

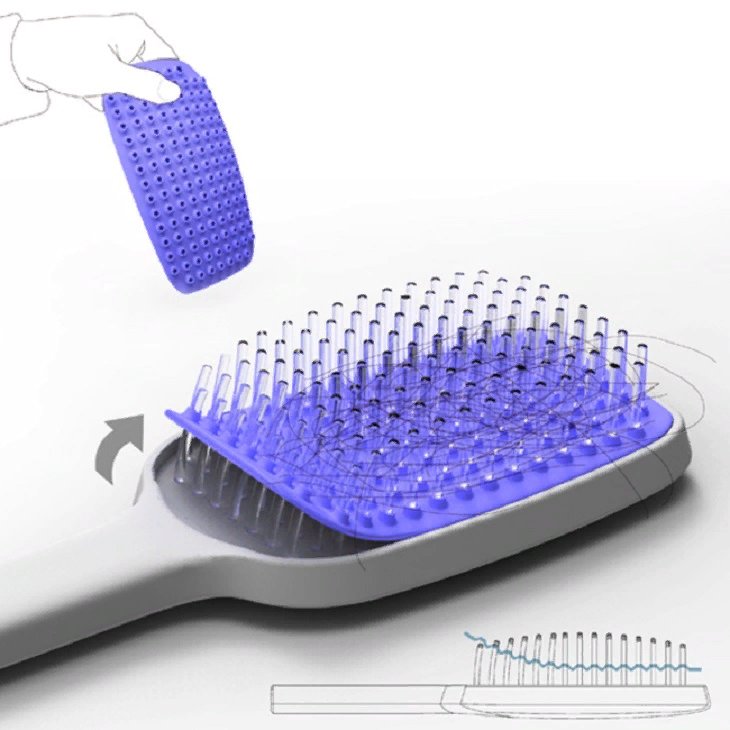

Meanwhile, it turns out that a similar new design is being offered for a far less significant purpose – just to make it easier to remove the matted hair from a hairbrush.

Naturally this kind of design is not thought of for its effect on the life of a brush. Ah, well, at least we have some guidance when it comes time to get serious about the Zero Waste of brushes.