Throughout this article it is essential to understand that “plastic” is not a simple material of no complexity until it is assembled or designed into a part. Some very sophisticated assembly is needed to push molecules into alignment and connection and that assembly takes lots of money, time and effort, likely more than that needed to assemble fibers into clothing or transistors into computers. All dedicated molecules represent high levels of hard won assembly which must be conserved through reuse. Burning and even composting are terribly destructive ideas which discard all of the expensive assembly that created the molecules.

RECENT REPORT – See shocking video exposé on the plastics industry from Frontline for 2019

A recent article in Vox reports on the many tons of plastic pellets ending up in waterways around the world from the spilling of pellets while loading or transporting. As usual, the industry suggests “recycling” as the answer, even though this is even more idiotic than usual, since the pellets are on the ground or seafloor or floating everywhere. But industry want all responses to be idiotic so that they can continue business as usual, making no changes. Why are these factories allowed to be near water? There is no reason other than governmental collusion in pollution. Why can’t they be forced to put in top of the line filling and transporting equipment and procedures with ZERO errors and spills? Because it would cost them some money, is the reason. It’s easier to call pollution an “externality” and let the public live with it and pay for all damages. Fines assessed to the company are just a cost of doing business. Read the article.

The bogus world convocations on solving waste issues just keep coming. Here’s one for 2023.

Google wants to be seen as the Prognosticator In Chief so they put together a supplement for the journal Nature and bound a copy in Scientific American to predict the future of sustainability of everything. Here is their one on plastics. Mostly they get it all wrong because they are still fixated on recycling. But things are changing. They even get a few things slightly right for a change, such as discussing ways to mark or identify each piece of plastic by its alloys and fillers. Of course at ZWI we have been urging this for thirty years.

They buy into the fantasy when they write: “…to make plastics more sustainable, recycling needs to be massively scaled up worldwide.” When you see writing like this, you know they have missed the boat and have no chance of improving sustainability. But they are becoming so desperate that they actually suggest changing plastic design to use fewer resins and fewer additives. Hooray! Another change we have urged for thirty years.

After 50 years of desperately invoking waste pickers to select high value items from piles of waste in poor countries, with absolutely nothing of value to show for it, they still try to mislead the reader into thinking this is a viable approach.

How could they not be desperate when they predict demand will rise to 1,100 millions tons a year by 2050. It never occurs to them to not meet a demand but to restrict manufacturing to actually needed and usable products which would have far less likelihood of discard, since they would be in the hands of owners, with an actual use for the product.

For decades, ZWI has urged the segregation of certain plastics, such as mylar polyester used for film backing, leading to its breakdown into its monomers, as one way to reuse some plastics. The recyclers are always tentatively supporting this, calling it chemical recycling, which is fine, except that they regard pyrolysis (burning) as one form of chemical recycling. They still are clueless. All these years, watching recycling fall flat on its face, and their vision still stops dead on more recycling. Pathetic!

_________________________________________________________________________

In a recent article in Science (August 2009) there was a long discussion of new ways to polymerize olefins (ethylene, propylene etc.) using different catalysts that join the polymers in all different ways to achieve many different properties.

In that article, it was taken for granted that “…Finding the balance between performance and price is critical to commercial success, as the customer will always adopt the cheapest solution that meets the performance criteria…”

While no one can doubt the importance of price, there is no mention anywhere in the article about the ability of the polymer to be reused. This simply does not enter into the author’s consciousness. If all of the polymer made by these newly developed methods is used once and then discarded into a dump, this is not seen to be of any importance. This is not considered to be part of the “greenness” equation. All that goes into greenness, according to the article, is whether the raw material comes from petroleum or sugarcane, no matter how soil is degraded or energy is squandered. In the industrial chemical field, discussions of green chemistry have been driven by the most conventional markers (frequently only toxicity and reduced solvent usage) but are not tied in important ways to planetary preservation.

So what path should polyolefin design take to address reusability? Of course, the best way to reuse a plastic part is to reuse it in its highest, complex function. A pump housing should be used in another pump as the same kind of housing, which can only be done if pump design is purposely controlled so that this kind of reuse is built in. But plastic materials are also highly complex molecular assemblies in their own right, aside from the kind of parts they are made into. It is incomparably better to maintain molecular complexity than to break down materials to carbon dioxide or other simple molecules, such as by burning them.

Plastic polymer chains are susceptible to many design parameters. Polyolefins are not necessarily made from long molecular chains that are identical, length after length. They can be combined with other kinds of monomers so that, in each molecule, a long run of polymerized olefins then give way to a run of a completely different kind of monomer (such as styrene or urethanes). The chains are separated into blocks. By combining blocks of different properties and different lengths, the properties of the macroscopic plastic can be fine tuned. This gives us a key way to build in one kind of reusability, as I will explain.

While polyolefin chains (polyethylene, polypropylene) are very difficult to break apart chemically, that is not true of all chains. For example, polyester chains can be broken apart fairly easily (there are factories based on this easy reaction and our bodies break apart the ester linkages of starch down to glucose molecules with no trouble). So if we want to be able to break apart polyolefin chains so that we can purify and reuse them, we could add in even a single polyester bond in the middle of a very long polyolefin chain and break the chain apart by the same methods used to break apart polyesters.

The neat part of doing this is that the small presence of the polyester will be so diluted in all the polyolefin that it will change the polyolefin properties almost not at all. Thus we can build in a major reuse capability without changing the plastic properties. Is this a win-win situation or what?

A very important place to apply this kind of modification would be in polyvinyl chloride (“vinyl, PVC”) design. The manufacturers proudly claim that their plastic cannot be reused, though I have never understood why they want to be so definite on this point. Certain environmentalists have proudly repeated this claim because they think it supports their campaign to ban all PVC entirely. But reusability will certainly never be designed into anything while the dump is always welcoming. Smugness will not solve any problems. The highest form of reuse, as formed parts, is already widely available. For example, much PVC ends up in the form of water pipe, which can be trimmed and reused many times. All PVC research needs to be bent toward reuse in every way possible. (see the local article on PVC pipe under Projects). Here is an article by a company that tried to reuse PVC in a foolishly simple minded way but found it impossible because the plastic had been in contact with many contaminants during its first use. PVC-Not-Reusable. Clearly more research is needed.

Three special problems:

- The solidity of thermosetting plastics

- The inseparability of laminates

- The molecular breakdown accompanying re-melting and re-extrusion.

Thermosetting: A recent article in Science (18 November 2011 p. 965) reveals some new research into the difference between thermosetting plastics, such as Bakelite, which have rigid forms and do not melt, and thermoplastic plastics such as polyethylene. They are developing ways to make plastics behave like thermosets when that is required, during their useful life, but release their rigid bonds and start to change shape when some kind of new energy is applied, such as light or heat. This could make it possible to have hard, rigid plastics that can nevertheless be induced to change their shapes into new ones when needed.

Laminates: Take a common case of lamination: the plastic sheets used to protect foods such as meats. Let’s assume that we have an outer layer of polyethylene because it is cheap and flexible, even though it has pores that allow oxygen to enter, laminated to an inner layer of a chlorinated PVC or a Saran which has no pores but is more expensive. Can we get the benefits of that sandwich without joining the two sheets together for all time?

For example, could the food be inside a bag of the Saran which was then inside a second bag of polyethylene to make it more portable? Is the lamination used only because it is technologically more “cute” to make a plastic sheet that appears to be a single sheet?

Or could there be a simple way to de-laminate the two different kinds of plastic using light or radiation or a chemical signal or ultrasound or heat? Plastic Delamination

The article reports on using a cyclohexylamine as the solvent. There is probably nothing special about this one solvent but it is probably typical in being fairly toxic, expensive and difficult to reuse. What happens to large amounts of cyclohexylamine after a few tons of lamination have been soaking in it, dissolving various organic molecules in the solvent? Distill it at considerable expense, leaving a residue of adhesives etc.? Throw it into a chemical dump – even more expensive, polluting and wasteful? Typically the report ignores the real problems and pretends to report on some amazing success. How about rethinking the whole lamination thing?

A Zero Waste principle forbids the joining of two dissimilar materials that cannot be separated or used as is. Lamination of plastics is a prime example.

Chemical and Engineering News (5-19-2014 p. 4) reports a new, hard thermoset based on 4,4′-oxydianiline and paraformaldehyde which sets up hard and yet can be hydrolyzed back to usable monomers by exposure to an acid. As always, it is best to reuse a formed shape without changing that shape but at least the entropic contribution from creating specialized molecules should be preserved, even if the higher function is lost.

Breakdown: Despite the naive claims of recyclers, you cannot just keep remelting plastic and reusing it. There is a cost in molecular integrity each time. Can chemists get around this obstacle? Isn’t it better to design parts so they can be reused forever, instead of having to be remelted into new products?

CAUTION: Chemistry ahead! Stop here if your vehicle is not equipped with chemical information devices!

Chemical and Engineering News, August 13, 2012, p. 32. In an article entitled Polymer Healing By Olefin Metathesis, it is announced that a new method has been developed that can heal the cracks that form in certain plastics from use or exposure to stresses. It reports a kind of magic glue, that can be introduced into a crack and then when the sides of the crack are pushed together, the broken polymer chains reform as new, long chains right across the crack, healing it as good as new. If this could be used in the field for actual plastic parts, as they suffer mechanical stress and crack, they could heal themselves for a longer life. This is just preliminary research at the moment.

Drawbacks so far:

- The trick is based on ruthenium, a rare and expensive metal in the platinum family.

- There is no suggestion yet that the plastic part can be dipped into the solution and then compressed to heal all the cracks.

- The polymer must contain an olefin (double) bond, which so far was only tried with cross-linked polybutadiene (a form of rubber).

On the brighter side, many polymers contain olefin bonds and other catalysts may work for other kinds of bonds. Not all repairs consist of replacing broken gears or burned out resistors. This is repair on a molecular level. Stay tuned.

In 2014, a new way to heal holes and cracks in plastics has been developed, in analogy to the way blood clots. Small channels run throughout the plastic filled with monomeric chemicals in long chains. When the plastic is broken, the channels are automatically opened to react and a gel fills the cracks or holes, then the gel solidifies and the hole is healed.

IMPLANTABLE MEDICAL DEVICES

A recent research report in Chemical and Engineering News (C&EN Dec 3, 2012 p. 32) explains that siloxane-polyether-urethane block copolymers are widely used in medical devices that are implanted in the human body. It has been found that these plastic copolymers have a route to breakdown at the ambient, wet and warm conditions of the body which consists of hydrolysis of some of the bonds in the plastic.

The article reports that research is being done to find out exactly which bonds are hydrolyzing. The only goal they view is the shortsighted one of making different plastics which last forever under ambient physiologic conditions. Important as far as it goes, but what other potential goals are opened up by such research?

A device that is implanted is not needed forever. Some are removed for cause, while others are found in corpses. Can they be removed for some kind of reuse?

Pacemakers are already harvested to some extent but how about extending that to other devices, such as these plastic ones?

Sure, we want these devices to last for a lifetime, but once that lifetime ends, and we remove them from a corpse, we might have industrial sized pile of plastic which incorporates all manner of other subsidiary devices. Pumps, metals, electronics. Once we understand exactly how hydrolysis takes place, could we create a plastic that hydrolyzes insignificantly at physiologic temperatures but very fast at, say, 200 degrees centigrade in superheated steam? Then the plastic monomers could be separately collected, distilled, purified and reused for new plastics without losing the molecular complexity inhering in the monomers. This is a Zero Waste approach. Redesign the product for a form of reuse that captures the high molecular complexity at least partially. It’s not as good as reusing the entire device for its original function in a new body, but it’s a start.

PLASTIC BREAKDOWN

It is practically taken for granted that plastics are annoying because they will last forever, filling up biological niches as they are eaten by animals and geographic niches as they sit in dumps forever. These notions were developed in the early days of plastic, when hardly any time had elapsed. To anyone paying attention, it was always obvious that sunlight had a destructive effect on plastic. You may have noticed that the ubiquitous, white plastic buckets used for paint, dog food and other products, crack and fall apart after a few years outside. This is ultraviolet attack on the polyethylene chains in the plastic. The same thing happens to polyethylene chairs and tables and, with regrets, to plastic covers for greenhouse frames. However, in 2016, after some time has now passed since the original creation of plastic devices, it is becoming obvious that plastics will self destruct all by themselves. They may get some help from oxygen or trace gases in the air or from timed breakdown or from the migration of some of the fillers and plasticizers out of the body of the plastic. The problem detailed in Scientific American, April 2016, p. 74 et.seq. concerns astronaut spacesuits on display in the Smithsonian museum. Here is an excerpt:

The trouble is the construction material: plastic. Most people think plastics last forever, which makes them a bane to the environment. But although the repeating units of carbon, oxygen, hydrogen and other elements in plastic have a long lifetime, the overall chains – synthetic polymers – do not age well. Light conspires with oxygen and temperature to weaken the bonds that hold the units together. Then chemicals added to plastics to make them bendable or colorful migrate outward, making the surface sticky and wet and perfect for attracting dirt. The polycarbonate spacesuit visor, Young thinks, was leaching out a substance added to make it easier to shape.

Priceless 20th century art is in serious trouble as well. In that era, Andy Warhol, David Hockney and Mark Rothko all used acrylic paint – a plastic polymer popularized in the 1940’s as an alternative to traditional oil paint. Plastic is in fact a building block of much of our recent cultural heritage, including important designer furniture, archival film, crash test dummies, the world’s first Lego pieces and Bakelite jewelry as well as the plastic sculptures made by the pop-art movement. “We now know that objects made of plastic are some of the most vulnerable in museum and gallery collections” says Yvonne Shashoua, a conservation scientist at the National Museum of Denmark and one of the first cultural heritage researchers to study plastic degradation.

The irony is that we moderns thought that we were leaving behind the era of soft, degradable materials and entering a world of digital permanence, where our creations would last forever. Instead, the situations seems to be exactly the reverse where some 5000 year old cellulose papyri can still be read, oil paintings can still be viewed and stone lasts for many millenia while floppy discs from ten years ago are already unreadable.

OCEAN GYRES

The term gyre is being applied to floating islands of waste plastic in the oceans that can cover areas the size of whole American states and slowly spin, thus gyres.

The source of these gyres is no secret. Most plastics are lighter than water so they float. Millions of tons of plastic goods intended for one short use (eating utensils, chairs, bags) are produced everywhere in the world. Then, after their one use, they are discarded. They are light and they blow around or float on streams and rivers into the ocean. The heavier pieces break down mechanically or from sunlight into small pieces that are mobile. Winds and tide push them together into gigantic piles. They also wash up on shores by the millions of tons.

A specific harm that they do is to mimic colorful food for marine animals, who eat them until their stomachs are so full of indigestible plastic that there is no room for real food and they starve.

In 2021, off the shores of Sri Lanka, 1680 tons of new plastic pellets, intended for making into plastic objects, spilled from a ship. The pellets completely covered the sand on nearby beaches, along with thousands of dead marine animals. It was the worst spill in history of plastic in the ocean. Read here: Giant Plastic Spill.

This, in a nutshell, is the story of global plastic waste. It represents a huge assault on our planet. But is the existence of unwanted debris the only, or even the main, waste of planetary resources? Hardly! No one in this field will ever mention the loss of raw materials, primarily petroleum but occasionally natural gas, or the gigantic waste of resources used in thousands of global factories to create the resins or to extrude the resins into short-term usable goods. In this society, driven by the personal or corporate profit motive, anything that can produce a profit is allowed – even encouraged – and the effect on living victims, nature or the planet is just an externality that others must bear or suffer from. Nothing is to be done. The profit motive rules uber alles.

The authorities seem to have nothing to contribute to the discussion on solving problems of global plastic excess. Here is an article from C&E News April 16, 2018 presuming to sum up solutions. Indeed! Solutions! No institution will allow itself to face solutions. Solutions threaten the primacy of rich and powerful corporations and their prostituted politicians. Solutions require changes in the way that plastic products are allowed to be created. Solutions will require laws and regulations which will restrict the ability of petroleum and plastics companies to fill our world with harmful crap. Sorry, all they can offer are 1) alarming warnings that time is running out, 2) money (for what? They have no idea) and 3) bogus, end-of-pipe fixes – they keep using that useless word, recycling – that conveniently leads to even more investment, for more profit, while the environment continues to groan from corporate depredation. Read article. PlasticWasteCandEN-4-16-18

Here is another article from a few months later that indulges in all the familiar handwringing while it tries to present some technical approaches. Unfortunately, every proposed change in polymerization or recovery is contaminated by the blinkered, unimaginative reliance on RECYCLING.  As pointed out in this website, recycling is embraced as a religion, even when it falls flat and offers no intelligent way out of problems. The next article suffers from that kind of theocratic thrashing as well. The sole kind of solution offered is to attempt to collect plastics which have already been dispersed into the environment and then assemble them i.e. recycle them, so as to convert them once again into monomers which can be chemically managed (distillation, filtration) to purify the monomers before repolymerizing them again. For plastics which can be effectively collected because their commercial usage is controlled (such as film backing which was a polyester – mylar) this is acceptable because at least it does not destroy the exquisitely wrought molecular complexity of the monomers. The particular newly proposed polymers have unknown properties while commercial uses of general plastics are exquisitely selected for their properties and designers are unlikely to find the new physical or processing properties attractive. For everything else, which is distributed too widely to collect or is contaminated by food or sea water or degraded by UV or oxygen, it is pie in the sky. Yet this is the only kind of change these so-called authorities can put forward. Meaningful changes in the design of goods, it seems, are prohibited, even though that is the only way to solve the identified problems. Read article.

As pointed out in this website, recycling is embraced as a religion, even when it falls flat and offers no intelligent way out of problems. The next article suffers from that kind of theocratic thrashing as well. The sole kind of solution offered is to attempt to collect plastics which have already been dispersed into the environment and then assemble them i.e. recycle them, so as to convert them once again into monomers which can be chemically managed (distillation, filtration) to purify the monomers before repolymerizing them again. For plastics which can be effectively collected because their commercial usage is controlled (such as film backing which was a polyester – mylar) this is acceptable because at least it does not destroy the exquisitely wrought molecular complexity of the monomers. The particular newly proposed polymers have unknown properties while commercial uses of general plastics are exquisitely selected for their properties and designers are unlikely to find the new physical or processing properties attractive. For everything else, which is distributed too widely to collect or is contaminated by food or sea water or degraded by UV or oxygen, it is pie in the sky. Yet this is the only kind of change these so-called authorities can put forward. Meaningful changes in the design of goods, it seems, are prohibited, even though that is the only way to solve the identified problems. Read article.

About once a year, some new magical solution to gyres is put forward and the mainstream press goes crazy explaining how this is going to eliminate the gyres and provide endless collection of either; 1. recyclable and reusable plastic or 2. endless energy by burning the collected plastic. The new solutions always involve some marine vehicle with a scoop that scoops up the plastic in the gyre and fills up a huge container (a ship, or a hold), and then transports it back to land where a recycler waves a magic wand over the collection to send it to recycling heaven. Even though the same idea keeps popping up regularly, every venture is promoted in the press like some divinely blessed brand new approach. Here is an article that brings just the fairly simple mechanical difficulties to the fore. OceanPlasticFail

Yes, it says that 31 million dollars was squandered for this Rube Goldberg invention. Meanwhile, not one dollar is spent to redesign plastic devices so that they don’t end up in the ocean in the first place.

Plastic gyres are being touted as the environmental problem of the age. Here is one more discussion of how tough it is to RECYCLE incompatible plastics while studiously ignoring the only solution that can actually solve the problem. Plastics Concern

In reading this article, you see the utility and appropriateness of recycling being analyzed and trashed quite capably. The recycling expert reports that 450,000 tons of unusable plastic (which will never be used) have been placed in storage already and that the feasible limit has been reached. Yet somehow, the idea that recycling is a failure that offers no answer is never allowed.

In 2019, it seems to have penetrated the consciousness of the faux-experts that scooping up plastics from the ocean is a guaranteed failure. This article points out that an effective solution will need to start upstream before plastics get into the gyre. Holy hell! Are these people finally getting it? Not to worry. They will never understand basic common sense. No, all they want to do is to put a scoop in every river on the planet to collect the mixed, trash plastic in rivers instead of the ocean. Every other feature will be the same. Collect and store for eventual (read: imaginary) recycling. How many rivers will need to be monitored this way. Google says there are 165 major rivers in the world and thousands of smaller ones. Here is a commercial boon worth having. Hundreds of plastic collectors in rivers and thousands more eventually mean a party for investors of capital in public-private projects financed by the public for private profit. Who would ever try to solve a prodigal problem with potential like this? Keep the plastic coming! PlasticCleanupRivers

No matter how recycling is seen to be a brainless answer, it is the only answer ever considered. I wish I could understand the psychological, social and business insanity displayed in such discussions. And the money wasted! Look at this brand new recycling company putting out a 250 million dollar bond. Will they find investors? Probably! Money for recycling. And scientists do their thing, hoping to contribute to the world. Polyethylene recycling?

And what about this one: Renew ELP.

This is the last you will hear about Renew ELP. They are in business to scoop up a floating pool of money and once they do, they are gone. There will never be any such “first” industrial factory because there have been dozens of similar boondoggles proposed before, only one of which was genuine (Eastman Chemical) and because the chemical theory on which it is being promoted is nonsense. Breaking down all conceivable plastic by exposing it to hot water – absurd! In the article on short selling below, the difficulty of purifying just one kind of monomer is invoked. Imagine the difficulty of recapturing ALL kinds of monomers all mixed together with all the junk the world can provide!

In 2019 and 2020, the penny finally dropped. Mad, desperate articles appeared everywhere. Micro and nano sized plastic particles, coming from the breakdown of every piece of plastic cavorting around the earth, are found in every cubic foot of air, every liter of water and every human body. Nothing is known about the biological significance of containing a few grams of nano-particles of plastic in your lungs, heart, blood and liver etc. Are the plastics companies worried? You betchum! Are their precious products going to be banned? Horrors! What can they do? Suddenly the literature was chock full of stories of how plastics were going to be collected and broken down into their monomers so that they can be distilled and purified and reused. Aah, at last. The problem will soon be solved. Sit quiet and don’t ban anything until we get back to you, in say, twenty years.

Following the revelation by Frontline that the plastics industry had been pulling the wool over the eyes of a gullible public for decades, and following research showing that tiny bits of plastic are so universally distributed that they are in all of our drinking water and all of our bodies, the plastics industry desperately cast about for projects and companies to claim to be doing depolymerization to hold up to the public to show them that the problem was under control. But once in a great while, the Great Wizard of Oz comes out from behind the curtain and we get to see a truth. This article reports that there was money to be made by betting against a company that was only a front. Read article.

In 2022 the UN gets into the act with a commission that will study the plastics problem. Article. What do you think? Will anyone have the balls to change the way that plastic is designed and manufactured? Lately the news is full of new recycling ventures (no redesign or reuse). Here are some: Plastic 2022 (they canceled their $680 million plant because they could not demonstrate their imaginary technology) and, Polystyrene Catalyst, and Plastic-Recyc-Future.pdf Recycling Future 10-20 and MixedPlasticRecycling.

Recycling fails, fails and fails but they come up with nothing but more recycling. Oh, my poor, poor, gullible brothers and sisters!

| HOW MUCH PLASTIC? In 1967 Mike Nichols gave us the classic film The Graduate in which Dustin Hoffman was urged to invest in Plastics. Plastic was just taking off as an everyday consumer product. By 2017, the world would be producing 348 million metric tons of it every year.

Since the 1950’s, we have produced 3.8 billion metric tons (a ton for every year the earth has existed) of plastic waste – the equivalent in weight of 25,000 Empire State Buildings. That’s a lot of plastic. And most of it is single use, ending up in dumps or littering the environment – never to be reused or recycled. At our peak, we recycled only 9 percent of plastics, today it’s even less. From the Earth Island Institute In 2023, Earth Action estimates plastic waste to amount to 159 million tons annually. They think that takes us just past the ability to manage it properly. Oh sure! We had no problem with 158 million tons, but why oh why (wringing hands) did you have to go and discard that extra million tons. Fie on thee!

|

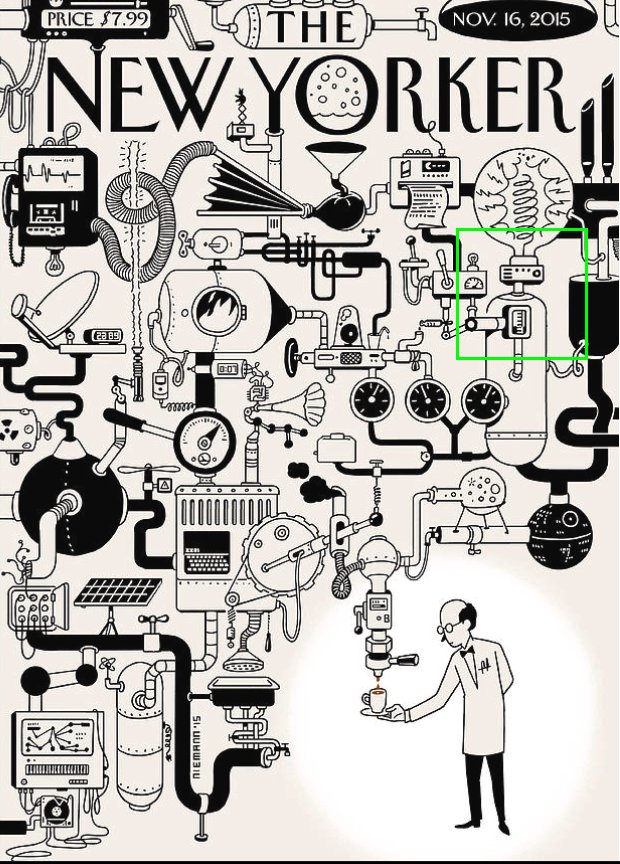

The fact is that while certain depolymerizing is real and can contribute, most of it is simple greenwashing, a phony response to a problem to make the polluter look like he is doing something. I think this cover from The New Yorker sums it up. A whole lot of equipment thrashing around to deliver – well, nothing really. A cup of coffee.